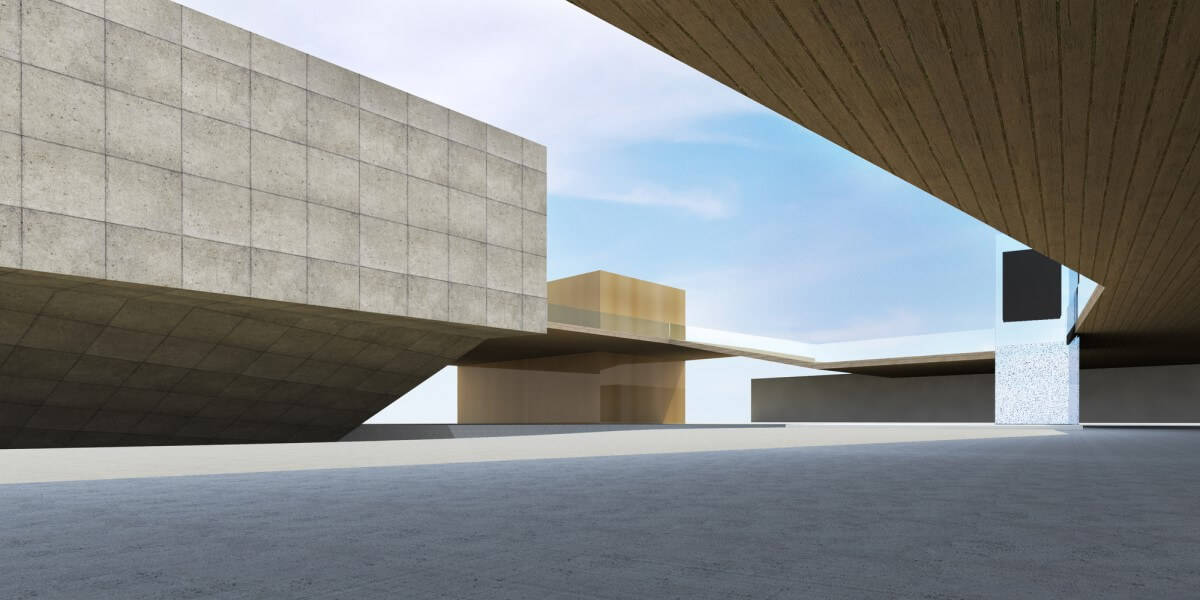

Wood and concrete are both widely-used materials in construction. For years, these two materials have been used in some of the most iconic buildings throughout the world.

Wood is lighter and is easy to work with, long-lasting, and results in less thermal bridging. Concrete, on the other hand, allows for the design of resilient and robust buildings.

The rest of this article will give you an overview of each construction material, that is, wood and concrete. You will also get to know the pros and cons of each and the factors to consider when selecting building materials.

A Basic Overview of Using Wood in Construction

Populations throughout the world have embraced wood construction over the years. Wood has inherently complex properties, but humans have harnessed these unique characteristics successfully. Wood is used to build various structures such as boats, houses, furniture, and interior décor.

Traditionally, wood has been classified into two categories: softwood (cone-bearing trees) and hardwood (leaf-bearing). Hardwoods are frequently used in wall, floor, and ceiling construction, while softwoods are used to make window frames, furniture, and doors. Today, there is also the inclusion of engineered wood which is often used in construction.

Engineered wood is created from a fairly complicated fabrication process where veneers, wood strands, other forms of wood, and fibers are joined to create composite material used in specific construction applications. Some of these engineered woods include glue-laminated timber, oriented strand board, particleboard, and plywood. These products are used in industrial, commercial, and residential construction.

One advantage of wood that makes it popular is that it is a natural product, making it affordable and readily available. Wood can be cut into different shapes and sizes. It is environmentally sustainable because it is renewable and provides insulation against the cold. Other than these, there are numerous advantages and disadvantages of using wood.

Pros of Wood in Construction

Wood has been used as a material in construction for many years. Although there is a desire to reduce its use due to environmental reasons, its benefits still outweigh those of other products. Some of its pros are:

Tensile Strength

Wood is physically stiff and robust. Compared to other materials, it’s also flexible and light. Wood has an annual-ring-and-gain structure, meaning you can snap or bend it. However, you cannot compress or stretch it by pulling it on the opposite side since it’s anisotropic. Compared to its tensile strength, wood is light.

Different types of wood have different strengths, but essentially, their tensile strength allows them to support their weight better than other materials. This reduces the requirements for support in different building designs and allows for greater spaces. It also makes it an excellent choice for heavy building materials like structural beams.

Electrical and Thermal Insulation

Wood has thermal properties that give it an advantage in terms of resistance to high temperatures. As the heat increases, the wood dries up and becomes stronger. It has low conductivity to heat, which is beneficial. This property allows it to be applied in various parts of the building, like handles, doors, floors, ceilings, and walls.

Wood, unlike other materials such as steel, is resistant to electric currents. It is, therefore, optimal for electrical insulation. In homes where there are many electrical appliances, this property provides some degree of safety.

Sustainability

Wood is renewable in that it can be grown and regrown. For every old tree that is cut down, a new one can be planted. This allows for more sustainable use of wood that doesn’t cause damage to the planet. This also makes it readily available locally in many areas. As such, building owners save on transportation costs from the milling industry to the construction site.

Acoustic Properties

Wood provides acoustic properties such as echo and sound absorption. For this reason, it is highly sought in structures where these acoustic properties come in handy. They include social and concert halls. Rather than reflecting or amplifying sound, wood absorbs it, reducing noise levels in offices and living places for additional comfort.

Aesthetic Beauty

One of the most appealing aspects of wood is its natural beauty and visual warmth. Long favored by architects for interior detailing, wood is also used on exterior facades to enhance a building’s aesthetic beauty.There are a variety of wood types used in construction. Softwoods such as beach, pine, ash, cedar, hickory, and birch are ideal to make window frames, doors, and furniture. Hardwoods such as maple, cherry, oak, teak, walnut, and mahogany are often used to construct floors, walls, and ceilings.

Environmentally Friendly

Recently, there have been high ecological concerns to prevent deforestation by minimizing wood used in construction and possibly managing the greenhouse effect. However, wood acts as storage for carbon that is responsible for greenhouse gasses. With the policies of planting trees when you cut down others, the environment is being protected while benefiting the contractor and occupants.

Wood is a natural product, and as such, it emits lower levels of carbon-dioxide gases and VOCs (Volatile Organic Compounds). Instead, wood relaxes the occupants of a home by giving off a natural organic compound. Other building materials such as concrete and steel are non-biodegradable. However, wood, when disposed of, breaks down quickly and replenishes the soil.

Easy Manufacture

The manufacturing process of wood is fairly simple because wood is readily available, compared to other materials such as concrete and steel. There is less environmental impact and production of wastewater in the wood manufacturing process compared to steel. Byproducts such as barks and chips come in handy as biofuel in lumber mills, facilitating the reduction in fossil fuel burden.

Systems for measuring moisture like Grade Recovery Program and Wagner Meters’ Moisture Management enable the lumber mills to produce less waste and sub-grade materials while maximizing efficiency.

Energy Efficiency

The thermal insulation properties of wood make it relatively energy-efficient. This essentially means that it retains warmth in cold temperatures hence saving on costs of air conditioning. When used for flooring, it saves on the need for heating, especially in very cold temperatures during wintertime. Additionally, because wood is readily available it does not require a lot of energy during manufacture.

Cons of Wood in Construction

Though wood has traditionally been used in construction due to its natural qualities, the fact that it is plant-based makes it sensitive to weather and environmental conditions. In addition, because it is a natural material, it is susceptible to certain environmental factors.

Risk of Rotting and Pest-Infestation

Wood is non-resistant to water and moist conditions. Over time, even treated wood will be unable to withstand moisture, therefore being susceptible to fungus, pests, and wet rot.

Fungi and pests can survive in temperatures of 25 to 30 degrees Celsius when there is adequate oxygen. Moisture creates a conducive environment for them to survive and digest it as their nutritional products.

Some of the insects responsible for wood deterioration by drilling and driving lines are marine borers, termites, carpenter ants, and powder post beetles. When the functionality of wood becomes compromised, it will require treatment or replacement, which can be very expensive.

Warping

Wood warps when it shrinks, swells, or twists due to age, environmental humidity, and temperature changes. As a hygroscopic material, wood will absorb surrounding vapors that are condensable and lose its moisture to air below the fiber saturation point. Warping results in reduced functionality of areas that require fine calculations, such as window frames and doors, when the environment changes against specific requirements.

Burning Risks

Where safety against fires is a concern, wood is not an ideal construction material. Wood quickly burns, and in worse-case scenarios, treated wood emits toxic chemicals like arsenic that is fatal and can cause death in closed spaces. Thick wood can extend the burning point, but engineered materials like I-joists or oriented strand boards are highly combustible and spread the fire very fast.

Fast-Aging and High Maintenance

Timber, if left natural and unpainted, as it ages, acquires a silver look. Wood requires a lot of maintenance, such as treatments, repainting, and repairs that are very expensive to retain its youthful appeal. After some years, wood easily weakens due to environmental and weather changes, and at times, this can pose safety hazards if not dealt with immediately.

A Basic Overview of Using Concrete in Construction

Concrete is a common, strong, and vital element used in building many types of structures such as pavement, parking lots, foundations, fences, building walls, bridges, and roads. Concrete undergoes a chemical process known as hydration, where it hardens and solidifies after mixing with water and placement. Concrete is made by mixing cement, sand, aggregate, small stones, water, and gravel to produce a stone-like material.

Hydraulic cement-based concrete was invented by the Romans, and improved upon and popularized by the British. Today, all over the world, people use over 6 billion tons of concrete annually. Concrete is porous depending on the spaces trapped by air voids during the mixing process and capillary pores filled with water after mixing.

Concrete is expected to achieve particular qualities such as wear-resistance, thawing and freezing resistance, tough strength, low permeability, and water-tightness by observing a low water-cement ratio. Additional admixtures to the concrete are used to achieve particular goals like reducing the curing time.

Pros of Concrete in Construction

Concrete is an integral building commodity and is widely used. Compared to other materials, concrete offers unique advantages like:

Economical

The cost of concrete production, in comparison to other engineered materials, is very low. Its major ingredients, water, aggregates, and cement, are locally available in the markets at low costs. Its availability, resilience, durability, energy efficiency, and low maintenance requirements reduce operational and maintenance costs, making it economical. Insurance costs are also lower compared to those of other materials.

Durable

Concrete becomes stronger as it ages and lasts longer than other materials. At ambient or regular room temperature, concrete sets, hardens and gains strength because it bonds in low-temperatures. Irrespective of the weather conditions, concrete retains its strength, hence its durability. However, its strength can be optimized by the use of admixtures.

Energy-Efficient

Concrete can store its thermal mass, which helps in moderating in-house temperatures, as well as reducing the cooling and heating demands by up to 8%. When used with technologies like hydronic or geothermal heating, cooling systems, and radiant floors, concrete improves energy efficiency by 70%.

In the event that services such as water, heating fuel, or power are lost, a concrete building improves the “passive survivability” by minimizing energy demands, therefore increasing comfort for the occupants. When used in pavement construction, concrete is energy-efficient in various ways.

Studies show that compared to asphalt pavements, concrete requires only a third of primary energy in rehabilitation, maintenance, and construction. Its rigid surface reduces fuel consumption by vehicles and emissions of energy by heavy trucks by up to 7%. There is a reduction in the heat-island effect due to their light color that in turn lowers exterior lighting and cooling requirements.

Water and Heat-Resistant

The chemicals in water can induce concrete corrosion. However, in comparison to wood and steel, concrete has a higher tolerance level that prevents serious deterioration and compromise in quality. Due to this aspect, concrete is usable in various underwater applications such as canals, pipelines, dams, waterfronts, and lining structures.

In pure water, concrete doesn’t deteriorate as it does in impure water, with additives of carbon dioxide, chlorides, and sulfates responsible for its corrosion. Concrete is a poor heat conductor. It can withstand and tolerate a considerable amount of heat for about 2 to 6 hours. In case of a fire, this is sufficient time for rescue operations to arrive and contain it.

Lowest Emissions

Concrete is completely inert when cured and will not emit any toxic compounds, volatile organic compounds, or gases. Innovations like Contempra that cure concrete with carbon dioxide instead of water make the structures possess the lowest carbon components in their life cycle. Concrete, therefore, emits carbon that is 6% less intensive than that of wood.

Versatile

Concrete is functional and robust when hardened, but its plasticity allows designers to craft it into different surfaces, textures, and shapes when it’s freshly mixed. There are innovations like photocatalytic, previous, and ultra-high performance concrete. They have enabled new and creative uses, as well as made address of sustainability challenges possible.

Adaptive Reusability and Recyclable

Concrete buildings are strong, fire and water-resistant, and have sound attenuation. For these reasons, during their service life, they are easily convertible into other types of occupancy. Re-using these buildings helps in environmental conservation and resource preservation through the limitation of urban sprawls.

Concrete can be used as a sub-base in parking lots, roadbeds, riprap for shorelines, and gabion walls by recycling it as an aggregate or granular material. The use of concrete waste reduces environmental impacts during new construction, where virgin material would be required.

Low to Zero Maintenance Requirements

Concrete buildings do not require regular applications such as painting or coating for protection. Concrete holds its integrity and shapes for years without the need for intervention. The coatings are redone and replaced routinely, therefore lowering the cost of maintenance compared to that of wood.

Cons of Concrete in Construction

Though concrete is a widely used construction material, there are many disadvantages associated with it. They can be modified by adding admixtures or changing the concrete ingredients and structure, but there will still be limitations such as:

Quasi-Brittle Material

Concrete is a quasi-brittle material in that it exhibits straining and softening characteristics. It undergoes minimal deformations without warning before failure. Concrete has a significantly low toughness that contributes to its failure. It is paired with steel to enhance tension and compression loads effectively.

Low Ductility and Tensile Strength

The low tensile strength of concrete results in crack formations, while shrinkage occurs due to drying or expansion due to moisture. Therefore, there is a need to reinforce it with reinforcing bars and to provide construction joints to absorb the natural expansion and contraction of the material. Due to its low ductility, concrete may experience creeps that result in deformation with time. It is, therefore, necessary to make careful considerations for tall buildings that sustain heavy loads.

Formwork Requirement

Formwork is necessary when molding liquid concrete into shape and supporting its weight. Procurement and installation of the formwork are costly and require a lot of time and intensive labor to install. There are innovations of prefabrication and pre-casting to eliminate these limitations.

Lengthy Curing Time

For concrete to attain the specified compressive strength, it has to cure for 28 days after being cast. It also requires a proper ambient temperature that is controlled for a month to develop full strength. The curing period can be reduced by incorporating admixtures or microwave and steam curing. However, these add to the cost.

Demands Skilled Labor and Strict Quality Control

Concrete construction requires skilled labor and strict quality control when placing, curing, and mixing it. This ensures that the concrete is of superior quality. Otherwise, the concrete will experience performance issues, low durability, and strength. In some cases, specialized machinery is needed, especially during high-rise construction, to maintain its quality and make work easy.

Considerations to Make When Choosing a Building Material

When building a home or commercial building, the material used is responsible not only for the overall appearance but also for its strength and longevity. When choosing the building material consider the following factors:

Cost-Effectiveness

Prices differ significantly when it comes to construction materials. Although there are a variety of materials to choose from, it’s important to create a cost-benefit analysis. The cheapest material is not always the best. However, as long as other needs such as durability are met, a cost-effective material that fits within your budget can work.

Aesthetics

Aesthetics can play an important role in the selection of a building material. The structure should have a good appearance. From the walls and finishings, the selected building material should help to achieve the desired look.

Structure Type

The type of structure being built also determines the type of material used. For example, in the case of a high-rise building, steel or concrete would likely be the best option. Wood is generally used for low-rise buildings. In the case of a commercial building where there is a risk of fire, wood may not be an ideal option because it quickly burns compared to concrete.

Availability

Usually, it’s best to select a material that is locally and readily available. This way it can be delivered conveniently while avoiding delays. The availability of building materials also plays a role in reducing transportation costs compared to having to transport them over long distances.

Performance Requirements

The selected building material should possess particular engineering characteristics for it to perform effectively. These characteristics include strength, durability, soundproofing, fire, and water resistance.

A construction material should have structural capabilities to bear the building loads. Its properties should ensure that occupants can live comfortably without experiencing any adverse effects such as chemical emissions.

Climatic and Environmental Factors

Climate plays a vital role in determining building material selection. For example, in very cold areas or during winter, wood can be an excellent choice because of its insulation properties. In tropical areas or during summer, concrete is able to keep the building cool. Overall, this would save on air conditioning costs during these seasons, depending on the construction material.The environment has, for decades, been disregarded when it comes to construction. However, environmental concerns such as the use of raw materials, depletion of natural resources, chemical emissions, energy content, and global warming are being considered more and more today.

Maintenance

Buildings need maintenance in order to retain their aesthetic beauty, durability, and safety. Material selection needs to consider whether it will be easy to maintain, how frequently it’s required, and the costs that will be incurred.

A material that is of good quality will usually require less and more affordable maintenance. Cheap construction materials may fit within a short-term budget in the beginning but will cost more in the future.

Construction Process

Different building materials have different construction processes. Some may require specialized personnel and machinery, hence are more costly.

In other cases, the construction site will require more work such as clearing debris, leveling the ground, and digging deeper for a more stable foundation. The safety of workers is also essential when a material requires a lot of work and the use of risky machinery.

Supplier

A reliable supplier will go a long way in ensuring quality materials and excellent service. Quality materials give buildings the desired outcome and make them long-lasting. A reliable supplier will also offer you service like transportation to the site and sometimes delivery when there are sudden requirements.

It’s generally a good idea to work with a local supplier and check for reviews or recommendations from former customers.

Sustainability

The construction industry is evolving fast. While there is growth in demand for concrete materials, there is also an increase in demand for reusable and eco-friendly materials. Renewable materials such as wood reduce the demand for future production of new materials. The construction process also determines if the materials can be reused.

Conclusion

Wood and concrete are popular construction materials that offer different advantages and disadvantages. Building owners should consider maintenance, availability, supplier, climatic and environmental conditions, the type of structure, sustainability, the construction process, and durability before making a purchase.

Concrete has advantages such as low maintenance requirements, versatility, durability, and water resistance, and it has disadvantages such as lengthy curing time, low tensile strength, and quasi-brittleness. Wood possesses thermal insulation properties, aesthetic beauty, and is environmentally friendly. However, it is susceptible to pest infestation and rotting due to moisture penetration.

Sources

- Understand Building Construction: Wood/Timber/ Lumber as a Construction Material

- RTF: 8 Things to consider while choosing materials for your project

- Civil RnD: 7 Factors Influencing the Selection of Building Materials

- The Herald: Factors to consider when choosing building materials

- Hunker: The Disadvantages of Wood

- Team Engineering: Pros & Cons of Wood as a Building Material

- Wagner Meters: Advantages of Wood as a Building Material

- Pro Crew: Concrete in Construction; its Uses, Advantages, and Types

- Rediscover Concrete: The Benefits of Concrete

- Civil Digital: Why Concrete

- Lafarge: 10 Benefits of Concrete over other building materials

- Engineering Civil: Limitations of Concrete; 8 Reasons

- About Civil.com: Disadvantages of Concrete in Construction